PVC (wood plastic) crust foam boardadopts celuka technology to foam. compared with the surface of the free

foaming, it is not only flat and smooth, but also it is featured by the

stronger is much better than the free foaming body. PVC (wood plastic)

crust foam board production line is composed of conical twin screw

extruder, board die, vacuum calibration, and eight rollers for hauling

as the components of the auxiliary machine. the application prospect is

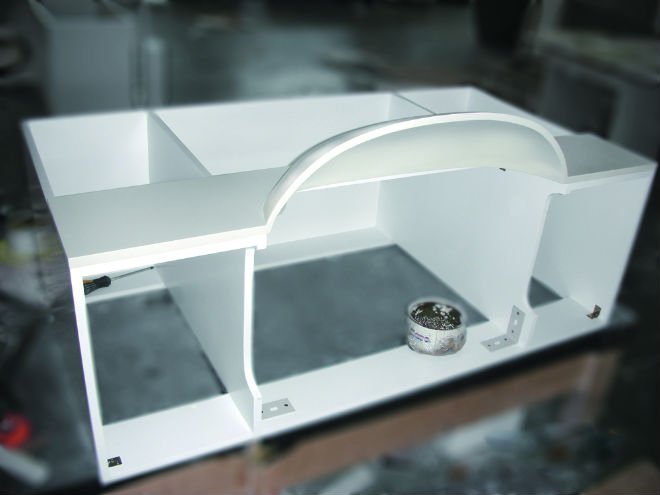

widely, it is use in high-end furniture, cabinets, advertising letter

materials, building decoration material of automobiles, trains, ships,

etc.

it is also called PVC construction formwork panel production

line, PVC cabinet/bathroom board extrusion line, PVC advertising

board/panel making machine, PVC package board/plate production line, PVC

furniture board production line

Introduction

PVC (wood plastic) crust foam boardadopts celuka technology to foam. compared with the surface of the free

foaming, it is not only flat and smooth, but also it is featured by the

stronger is much better than the free foaming body. PVC (wood plastic)

crust foam board production line is composed of conical twin screw

extruder, board die, vacuum calibration, and eight rollers for hauling

as the components of the auxiliary machine. the application prospect is

widely, it is use in high-end furniture, cabinets, advertising letter

materials, building decoration material of automobiles, trains, ships,

etc.

it is also called PVC construction formwork panel production line, PVC cabinet/bathroom board extrusion line, PVC advertising board/panel making machine, PVC package board/plate production line, PVC furniture board production line

Features

Products Features

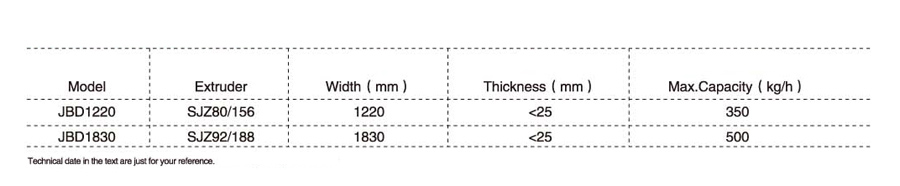

Specification

1. waterproof and mould proof

2 .widely used in kitchen and washroom cabinet

3. thickness from 1mm to 25mm, different density

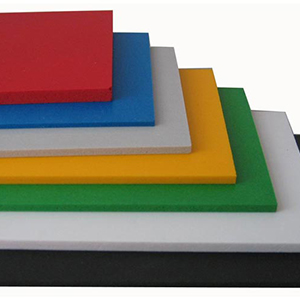

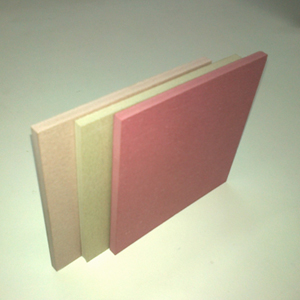

We are specialized manufacturing PVC foam board.There are 2 kinds of PVC foam board, one is Common PVC foam board with white surface, the other is called Exclusive PVC foam board with colorful servise.

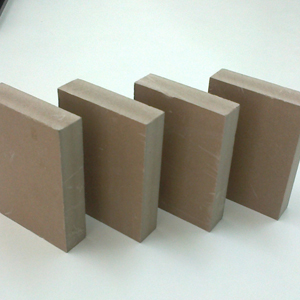

The PVC foam board is made through foaming and pressing

into shape with additive. It is widely used in Sanitaryware,

Construction material and Advertising material.

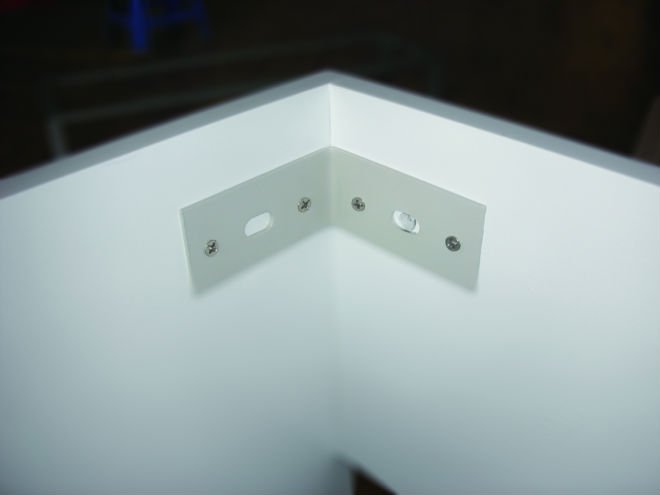

PVC foam board has its characteristics of easily sawed, bonded, nailed, joint and hot moulding.

Features:

1. Waterproofing.

2. Fire retardant and self-extinguishing.

3. Heat preservation.

4. Sound-insulated.

5. Insulation.

6. Non-corrosion.

7. Non-toxic.

8. Tough, rigid with the high impact strength.

9. Stable color retention.

10. Dampproof.

11. Anti - deformed

Applications:

1. Building outdoor wall board, indoor decoration board, partition board in office and house.

2. Screen printing, flat solvent printing, engraving, billboard and exhibition display.

3. Chemical anti corrosion project, special cold project, environmental protection

4. Sanitarywares, kitchen cabinet, washroom cabinet.

Specifications:

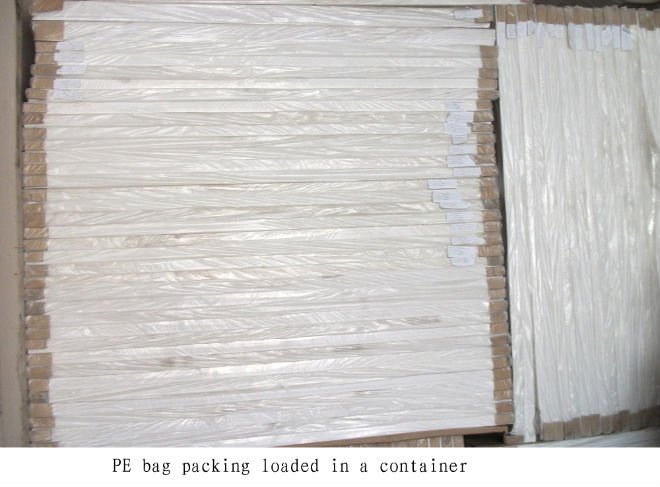

1 width: 915mm or 1220mm,

2 Length: 2440mm or as per your requirement,

3 Thickness: From 1mm to 25mm

4 Density: from 0.5 to 0.8

5 Color, white, wood, or any other color as per your requirement