The special detachment type mixing screw and the standard designed die with spiral structure & reasonable channel are applicable to produce pipes with smooth inside and outside face.

Introduction

The special detachment type mixing screw and the standard designed die with spiral structure & reasonable channel are applicable to produce pipes with smooth inside and outside face. The helix apportionment style different body and big flow space assure the melting material has enough stay time. Optimal low melting temperature result in little internal pipe stress, smooth inner and outer pipe surfaces.Unique sizing and cooling mode is capable of producing pipe scope 50-200 mm,production speed is up to 0.6~1.5 m/min

Features

●Standard design pipes die

●Spiral distribution Spiral distribution type shunting body, large space of flows, ensure the melt has enough time to stay.

●Excellent design of low melting temperature, internal stress of pipes is small, inside and outside has smooth surface.

●High

flexibility, apply to all of the polyolefin materials, extrude two

layers, three layers of different specifications and usage of spiral

enhanced pipes.

●The

optimization design of the copper spiral forming diameter entry point

has advance cooling device and strong absorption vacuum device,

applicable to pipes of high-speed extrusion.

●Special design of spray head bring high effective spray cooling.

●Longitudinal moving motor regulation, up and down, left and right can realize three-dimensional adjustment.

●Use stainless steel to produce box.

●High efficiency water pump and special spray head bring high effective spray cooling.

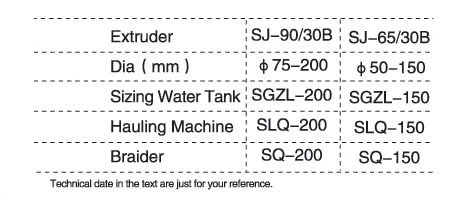

Specification

Products Features